Understanding Trickle Impregnation in eMotor Production

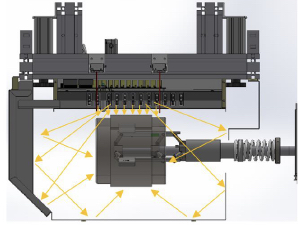

Trickle impregnation is a widely used method for applying insulating resin to the windings of stators and rotors in high-volume production. This process involves precisely controlling the resin flow to coat the windings while avoiding unnecessary coverage of the iron core. The resin is evenly distributed by continuously rotating the stator during the application, ensuring strong retention and reducing waste. Precision metering pumps draw resin from a tank and deliver it to a stator. Multiple nozzles ensure coverage of the outer and inner diameters of the windings. Trickle impregnation minimizes material usage, lowers emissions, and significantly reduces postprocess cleaning compared to traditional dipping methods.

Why Is Impregnation Necessary for Electrical Windings?

- Mechanical Strength – Strengthens the unsupported end windings and secures the coil placement within slots to resist mechanical stress.

- Prevention of Wear – Reduces the risk of wire insulation degradation due to vibration and movement.

- Improved Heat Dissipation – Replaces air gaps within windings with resin to enhance thermal conductivity and prevent overheating.

- Environmental Protection – Shields against moisture, dust, and other contaminants.

- Enhanced Electrical Insulation – Improves dielectric strength between coils and the motor frame.

Selecting the Right Resin for Trickle Impregnation

Several resin types, including epoxy, polyester, and polyetherimide resins, are available for trickling processes. These resins vary in composition, curing methods, and application requirements. Some resins are mixed at the point of application to maintain stability and predictability, while others are pre-mixed for simplified handling. The choice of resin depends on factors such as temperature stability, curing time, and the specific requirements of the stator design.

The Role of Heating in the Trickle Impregnation Process

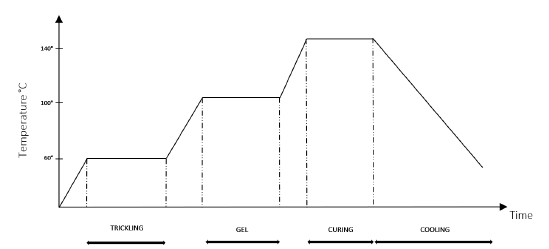

Heating is crucial in trickle impregnation, as it ensures proper resin flow, adherence, and curing. The heating process consists of three key stages:

- Preheating – Raises the stator temperature before resin application.

- Gelling – Partially solidifies the resin to prevent dripping.

- Curing – Fully hardens the resin, ensuring long-term durability.

Different heating technologies are used to achieve optimal resin curing while maintaining energy efficiency and process reliability.

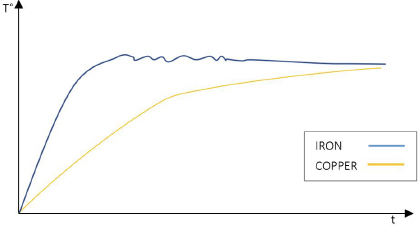

Below is a graph of a typical heat curve. The exact values are found on the resin manufacturer's datasheet.

Comparing Heating Technologies for Trickle Impregnation

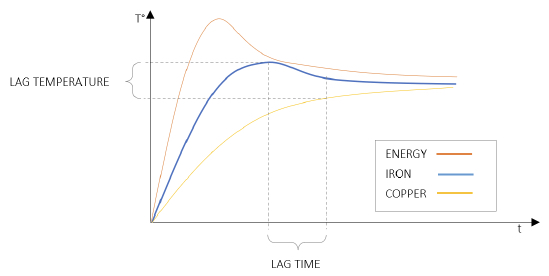

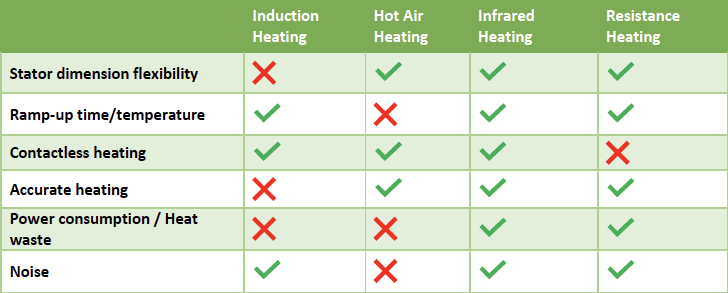

Induction Heating

- Uses an electromagnetic field to heat the stator, primarily focusing on the iron core.

- Heats rapidly but requires a lag time for the copper windings to reach the target temperature.

- Best suited for preheating but requires precise control to avoid overheating.

Hot Air

- Involves forced hot air circulation, similar to convection ovens.

- Ensures uniform heating but requires longer warm-up times and higher energy consumption.

- Effective for stator dipping applications where the entire structure needs to be heated.

Infrared Heating

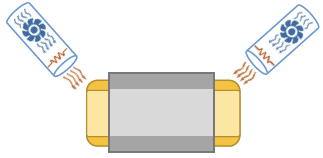

- Uses short-wave infrared (SWIR) radiation for targeted heating.

- It can be precisely controlled to heat only the required areas, such as copper windings.

- Reduces heat loss to the environment and speeds up processing time.

Resistance Heating

- Applies electric current directly to the copper windings to generate heat.

- Provides highly controlled heating, though it requires direct electrical connections.

- Suitable for trickle and dip processes but may require additional cleaning for excess resin.

Comparison of Heating Methods

Each heating method has distinct advantages and limitations. Selection depends on resin type, stator design, cleanliness requirements, material efficiency, cycle time, and automation compatibility.

The Advantages of Infrared Heating in Trickle Processes

Infrared heating emerges as a preferred solution for trickle impregnation due to its efficiency and precision. The

key benefits include:

- Targeted Heating – Directs energy to specific areas, reducing heat loss to non-essential components.

- Rapid Response – Quickly reaches the required temperature without prolonged warm-up times.

- Energy Efficiency – Lower energy consumption than hot air and induction methods.

- Minimal Maintenance – Infrared bulbs have long lifespans and require minimal upkeep.

Choosing the Best Heating Solution for Stator Impregnation

The choice of heating technology depends on factors such as resin type, stator design, required cycle time, and automation needs. While each method has strengths, infrared heating presents a flexible and energy-efficient alternative for high-volume production lines.

AWE Newtech has developed specialized Linear Infrared Heating and Trickling (LIRT) systems to optimize this process. These systems offer adaptive control for different stator sizes and configurations, enhancing production efficiency and quality.

For more details on how infrared heating can improve your trickling impregnation process, our technical team is available to discuss tailored solutions to meet your production needs.